Dough Moulding Compound, commonly known as DMC, is a versatile material that has captured the attention of various industries. But what exactly makes this compound so special? From its unique composition to its practical applications, DMC stands out in the world of molding materials. Whether you’re an engineer looking for innovative solutions or just curious about advanced manufacturing processes, understanding Dough Moulding Compound can unlock new opportunities and insights. Let’s dive into the fascinating world of DMC and explore why it continues to be a game-changer across multiple sectors.

What is Dough Moulding Compound (DMC)?

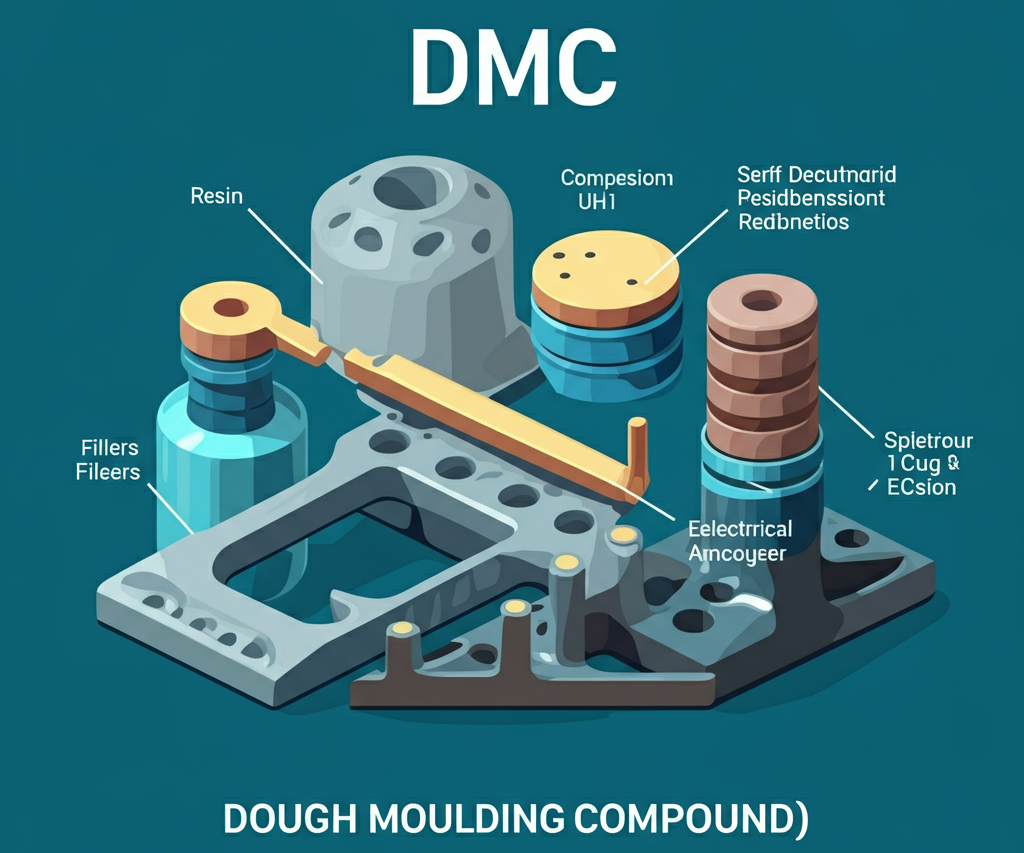

Dough Moulding Compound (DMC) is a type of thermosetting plastic that combines resin and fillers to create a malleable yet durable material. Unlike traditional molding compounds, DMC offers unique characteristics that make it suitable for various applications.

This compound is typically made by mixing unsaturated polyester resin with reinforcements like fiberglass or mineral fillers. The result is a dough-like substance that can be easily shaped before curing.

Once set, DMC exhibits impressive mechanical properties and resistance to heat and chemicals. This makes it ideal for producing complex shapes without compromising strength.

Its versatility allows manufacturers to use DMC in sectors ranging from automotive components to electrical casings, showcasing its adaptability across different industries. With such an extensive range of uses, understanding the nuances of this compound opens doors to innovative design possibilities.

Composition of DMC

Dough Moulding Compound (DMC) is primarily made from a blend of unsaturated polyester resins. These resins serve as the backbone, providing structural inty.

In addition to the resin, DMC contains fillers such as calcium carbonate or talc. These materials enhance the compound’s properties and reduce production costs.

To improve performance, additives like pigments and curing agents are incorporated. Pigments ensure that products can achieve various colors while maintaining their appearance over time.

Moreover, glass fibers may be included for added strength and durability. This reinforcement makes DMC ideal for demanding applications where resilience is crucial.

The precise formulation can vary depending on specific requirements in manufacturing processes or end-use applications. The versatility of its composition allows for tailored solutions across different industries.

Properties of DMC

Dough Moulding Compound, or DMC, boasts a range of impressive properties that make it a popular choice in various industries. One notable characteristic is its excellent mechanical strength. This durability allows DMC to withstand significant stress without compromising its structural inty.

Another key property is its thermal stability. DMC can endure high temperatures without deforming, making it suitable for applications that require heat resistance. Additionally, this compound exhibits good electrical insulation capabilities, which adds to its versatility in different environments.

Moreover, the material is lightweight yet rigid. This combination makes transportation and installation easier while enhancing overall efficiency in manufacturing processes.

One cannot overlook the material’s adaptability to various production methods. It can be easily molded into intricate shapes and designs, catering to diverse industrial needs with precision and reliability.

Advantages and Disadvantages of DMC

Dough Moulding Compound (DMC) offers several advantages that make it a popular choice in manufacturing. It boasts high strength and durability, which makes it ideal for heavy-duty applications. This material is also resistant to heat and chemicals, ensuring longevity in challenging environments.

On the downside, DMC can be more expensive than alternative materials. Its processing requires specialized equipment, which may increase initial setup costs for manufacturers.

Another drawback is its limited flexibility once cured. While this rigidity contributes to its strength, it can restrict design options compared to other molding compounds.

Moreover, recycling DMC poses challenges due to its thermosetting nature. Once set, it cannot be remolded or reshaped easily. This aspect raises environmental concerns as well as disposal issues at the end of a product’s life cycle.

Applications of DMC in Various Industries

Dough Moulding Compound (DMC) is widely utilized across various industries due to its versatile nature. In the automotive sector, DMC components such as engine covers and dashboards are common because of their durability and lightweight properties.

The electrical industry benefits from DMC’s excellent insulating characteristics. It’s used for manufacturing switchgear parts and housings that require high resistance to heat and electricity.

Construction also sees significant applications of DMC. It serves in producing decorative elements, panels, and fixtures thanks to its ability to mimic other materials while offering superior strength.

Moreover, the consumer goods market capitalizes on DMC for items like kitchenware and household appliances. Its resistance to chemicals ensures longevity in demanding environments. This adaptability highlights why many sectors prefer Dough Moulding Compound over traditional materials.

Comparison with other Molding Materials

When comparing Dough Moulding Compound (DMC) with other molding materials like thermoplastics and fiberglass, distinct advantages emerge. DMC exhibits superior thermal stability and dimensional accuracy. This makes it ideal for applications demanding precision.

Unlike traditional plastics, DMC is less prone to warping under heat. It retains its form even in challenging conditions, adding durability to the final product.

Fiberglass offers strength but can be costlier and more labor-intensive to process. DMC provides a balance of affordability without compromising quality.

Additionally, while metals deliver excellent strength, they come with weight drawbacks. DMC strikes an appealing compromise between lightweight properties and structural inty.

Many industries are shifting towards sustainable practices as well. Here again, DMC stands out due to its recyclability compared to some synthetic materials that present disposal challenges after their life cycle ends.

Future Developments and Innovations in DMC Technology

The future of Dough Moulding Compound (DMC) technology is poised for exciting advancements. As industries increasingly prioritize sustainability, eco-friendly formulations are on the horizon. These innovations aim to reduce environmental impact while maintaining performance.

Moreover, the integration of smart technologies in manufacturing processes will enhance precision and efficiency. Automated systems could streamline production, leading to faster turnaround times without compromising quality.

Research into advanced additives is also underway. These can improve not just durability but also thermal resistance and chemical stability, broadening DMC’s applications across various sectors.

Collaboration within industries will likely foster breakthroughs in application techniques as well. This teamwork can lead to customized solutions tailored for specific needs, enhancing versatility significantly.

As these developments unfold, staying informed about emerging trends will be crucial for businesses looking to leverage DMC’s full potential in their operations.

Conclusion

Dough Moulding Compound (DMC) is a fascinating material with unique qualities that make it highly valuable across various industries. Its composition, primarily based on unsaturated polyester resin along with fillers and additives, provides excellent mechanical properties and durability. The combination of strength, lightweight nature, and resistance to environmental factors sets DMC apart from other molding materials.

The advantages of using DMC are numerous. It offers high dimensional stability, quick curing times, and versatility in different applications. However, it’s essential to consider its disadvantages too—like the potential for brittleness under certain conditions or challenges related to recycling.

Industries ranging from automotive to construction benefit immensely from DMC’s performance qualities. Its versatile applications can be found in parts like electrical housings or decorative elements. As new technologies emerge, innovations within the field promise even greater enhancements in DMC formulation and usage.

As we look forward into future developments surrounding Dough Moulding Compound technology, it is clear that this material will continue evolving alongside industry demands. With ongoing research focusing on improved formulations aimed at sustainability and efficiency gains, the potential for growth remains vast.

Understanding Dough Moulding Compound opens up avenues not only for manufacturers but also for consumers seeking durable solutions without compromising quality or design aesthetics.